Control valves are a vital component of any installation. The correct selection has a significant impact on the stability and durability of the system, as well as on the quality of the product being cooled. With many years of experience in refrigeration applications using RTK valves, Wijbenga can determine the optimal design and configuration for every application. Each valve is custom-made and carefully engineered to meet specific operating conditions.

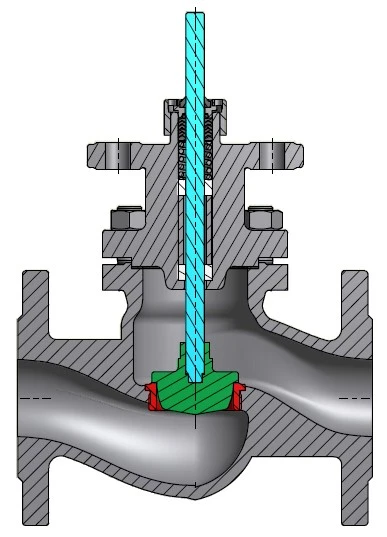

RTK valves are used for regulating or shutting off the flow of liquids, gases and liquid/gas mixtures in industrial piping systems. In refrigeration applications, the valves can be operated over a very wide temperature range and for design pressures from PS16 up to PS160. In addition, the valves are highly suitable for use as expansion valves. For large pressure differentials, special versions with hardened trim and multi-stage expansion are available. For 100% tight shut-off, the valves can be supplied with a PTFE seal.

The RTK control valves are equipped with reliable stem seals, suitable for almost all refrigerants including NH₃, CO₂ and most synthetic variants. For applications below 0 °C, a stem heater is applied to ensure operational reliability. Electric or pneumatic RTK actuators can be used, both available in numerous versions with a wide range of options.

Application examples

Expansion valve between high, intermediate and low pressure

Suction pressure control valve for (wet) evaporators

Regulation of liquid feed

Suction pressure control valve for compressors

Discharge pressure control valve

Control valve for secondary refrigerants

Control valve in oil circuits

Key features

CE-PED compliant

Reliable electric or pneumatic actuators available with many options

Various trims (parabolic cone, perforated cone, needle cone, mixing cone)

PTFE seal option

Hardened seat and stellite-hardened trim

Reliable stem seal with V-rings or bellows

Suitable for all natural and synthetic refrigerants

Available in sizes DN15 to DN400

Body in cast iron, cast steel or stainless steel

Valves available according to DIN or ANSI

Flanges flat-faced or grooved, according to DIN or ANSI

Coding

The RTK valves are coded with two letters and four digits. The codes have the following meaning:

Both letters and the first two digits

MV 52: motor-operated valves for a maximum force of 300 kg

MV 53: motor-operated valves for a maximum force of 600 kg

MV 54: motor-operated valves for a maximum force of 1000/1500 kg

PV 62: pneumatically operated valves with a diaphragm area of 280 cm²

PV 63: pneumatically operated valves with a diaphragm area of 530 cm²

PV 64: pneumatically operated valves with a diaphragm area of 1000 cm²

Third digit

1: two-way valve

2: three-way valve

Fourth digit